This subject has been in the back of my mind for nearly 20 years as I am fairly sure the guy involved in this is/was a Furniture design Tutor during my Uni days, he told me about his love of Grown furniture. It is a fascinating and completely sustainable way of splicing together vines and trees to create tough grown frames for stools, chairs and almost any required item. The subject deserves promotion as it is both ecologically and structurally sound as well as having truly holistic merit. The practice has survived thousands of years and now competes with post modern sculpture as a format of expression, this posting prompted by a recent BBC show on David Nash a globally famous wood sculptor as well as my own wood use and interest.

Simply; a tree or sapling is induced to splice and grown to a controlled frame giving a required shape.

A comprehensive interview with Chris (Independent Saturday 1st June 1996 David Davies) is republished below:

Plant your own furniture. Watch it grow.

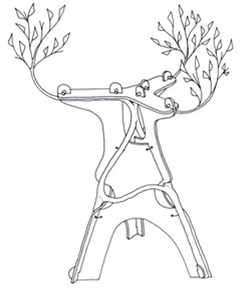

The way we use wood in furniture making can hardly be described as efficient. We're not particularly inventive, either; consider the trouble we go to in chopping up trees, moving pieces of wood from one place to another, machining them and gluing them back together. And judging by the contents of the average skip, all this effort often has less than satisfactory results. Furniture designer Chris Cattle is trying to change this with a more direct approach - growing furniture straight out of the ground.

"It may sound a bit crazy, but all I'm doing is changing the point in a tree's life at which I decide what its going to be," he explains. Based at Brunel University, High Wycombe, Mr Cattle has begun a living design experiment by planting 40 saplings arranged in various jigs designed to control the shape and grafting of the young trees. "I expect to get usable table and stool frames within about three to four years," he predicts.

If you think this is rather too long to wait for a piece of furniture, then you might have forgotten what any wooden article relies on: "If you compare the time spent growing perfectly straight trees ready for processing and making a conventional piece of furniture, my idea will be considerably quicker."

Tree species that grow rapidly, are flexible and graft easily are likely to work best. Mr Cattle has planted sycamore, maple, alder, cherry and beech and his experiment will determine which species will be the most suitable. The best time to harvest the crop of furniture is when the sap is down - the piece would then need to dry out before finishing.

Mr Cattle points out that his chair and table frames will be stronger than conventional furniture because the grain follows the shapes and because all the joints, rather than being stuck together, are formed through natural growth. But apart from functional advantages he also sees new design possibilities: "The opportunities are intriguing. I will be able to get shapes and angles that would be difficult and expensive to machine. The only real restrictions are in the size of pieces: large items would take too long to grow." To overcome this, he suggests a halfway point of growing large, shaped pieces that can be joined in the conventional way. The flat panels needed to make seats and table tops will also present something of a challenge although techniques for growing square bamboo posts for use in traditional Japanese houses are well established and could be adapted to British tree species.

A future where furniture growing has replaced manufacturing sounds bizarre but appealing - a non-industrial approach where intervention is minimal and the trees are left to get on with the production. Growing large quantities of furniture would need huge areas of land but Mr Cattle argues that his production method is feasible because grown furniture will last far longer than conventional pieces and growing can be scattered around the country on small-scale sites. "Relying on the sun's energy and avoiding the polluting aspects of machining, laminating and gluing is an attractive prospect. Furniture can be grown relatively near to where it's needed - DIY enthusiasts could use their own gardens."

However, on a rather more realistic note, Mr Cattle is resigned to his idea meeting considerable resistance. "Its a radical proposal that will demand quite a substantial rethink for both industry and the public; furniture will look more organic and shapes will be more flowing."

The concept of growing your own furniture is actually far from new - both the Egyptians and Greeks made chairs using this technique - but apart from agriculture implements and walking sticks with right angled handles, most controlled tree growth in recent times has been decorative.

Today, our fixation with the predictable results that industrial production lines offer has meant that skills in living design and the potential of controlled tree growth for practical uses have remained unexplored - until now.

Chris Cattle has a quiet conviction about his idea that draws you in - however crazy it sounds. "This is a move away from throw-away culture towards manufacturers becoming concerned for the life-cycle of a product," he says. "After all, a piece of grown furniture could produce the seeds for future designs."

A growth industry

1570-1305 BC Three-legged stools thought to be made from pieces of wood grown into curved shapes were commonplace in Ancient Egypt (an example is on display at the British Museum).

500 BC The legs of Greek Klismos chairs used wood that had been artificially trained in order to get correct curvature.

15-1600 Garden houses made from living trees originated in the Middle East and spread to Europe. There are accounts of a three-storey version at Cobham, Kent, which was large enough to hold 50 people.

Until 1940s grown pitchforks and walking sticks were common. The forks were traditionally produced in southern France with three or four branches pruned to make the prongs; walking sticks grown in Surrey were produced by planting saplings at an angle to the ground in order to produce right- angled handles.

1908 John Krubsack, a farmer in Wisconsin USA, grew a chair from seed using 28 box elder trees to form the legs, back and seat - it took 11 years to grow. ARTICLE ENDS.

(I Googled the following image to enhance this article RG – Krubsacks chair))

Chris actively promotes this process and I am happy to further the cause with the following links and articles:

http://www.arborsmith.com/index.html

(The site is a little hard on the eye but the information it contains is impressive) A huge amount of information here from a longstanding practitioner of Tree manipulation who has written a book on the subject. A blog too! http://www.arborsculpture.blogspot.com/

http://markprimack.com/pages/tree_circus/tree_circus.html

A terrific resource, Mark has researched thoroughly the history and use of Tree manipulation. Even as entertainment, a Tree circus! He obviously loves the subject and presentation is top notch.

As mentioned at the start of this posting I recently saw a BBC documentary on David Nash, wood sculptor. Personally I have always worked in wood and consider myself a wood Engineer/magician in the truest sense. Both understanding and respecting the material and being able to precisely make with it, or not as the wood type/case may be.

His approach to his work was a methodology I completely relate to and found it fascinating. Famously he lets the material in a raw state age and progress under atmospheric conditions.

He took the idea of a sculpture to new heights some decades back when he grew a sculpture from saplings creating; Ash dome. Directly linked to ancient furniture growing, British coppicing and Forest crafting. The circle completes.

David’s work also uses the process of burning and destruction to show the stages of life, following death of live wood. It never actually dies: The wood is cooked (Charred/charcoaled) to create its patina, or left to distort:

Interestingly the Nash piece below is labelled as made from Silver: Silver Egg. Though the look and feel directly link it to African wood sculpture in my opinion. Something I relate to via my African loudspeaker sculpture and finishing for one of my speaker products (www.rgproduct.com) image to follow.

David's Tripod-al piece, “Standing frame” combines the engineers tripod stability with the intoxication of a tree upturned yet still standing. Again the dark patina is powerful.

I see and feel identical thematic qualities as Nash’s in my approach and this is illustrated in a piece I created a few years back that apes the Ghanaian ancestor mask in form and patina (partly moulded from an original). Obviously the physical abstraction into an electronic based product then cast in modern resins is not lost on me but the aesthetic and conceptual elements are identical: Richard Grant Ghanaian Ancestor mask (female) loudspeaker :

The next step from celebrating Wood’s processes and death or the suspension of that process, the alternative to the aging process, and what we spend most of our time doing is trying to freeze the wood in an unnatural stable state. With rot proofers, shellac, varnishes and oils not to mention paints we hold fast against he natural aging dilemma. Time is frozen, the eternal moment. Trapped; the beauty of nature having to and making us work with it.

(The similarities to the modern cosmetics and surgery industries are seemingly stark).

This further leads to my fascination with trees and organic things growing through and assimilating man made objects. I will collate some images to illustrate this but also intend to photograph examples I see on my travels (and will post these up as and when, some from childhood play memories and locations)

A limb grows through a fence, a man made item, the tree slowly envelopes and traps the fence. The tree overcomes the obstacle, as humans overcome their obstacles. Be it instant or slow.

The biological processes at work here are fairly mind boggling, I intend to look into this at some point…

A terrific Blog with excellent examples of wood in sculpture and abstract expression:

http://www.genetologisch-onderzoek.nl/index.php/category/biologie/dendrology/

My current projects are leading into territory that encompasses all of the above in methodology and technology. I will report as things occur. R

No comments:

Post a Comment

Note: only a member of this blog may post a comment.